Historia del cliente: Granger Construction

El equipo de diseño y construcción logra las primeras marcas en centros de datos para Michigan

Resumen

Los proyectos complejos como los centros de datos generalmente no adoptan un enfoque de diseño y construcción. Pero en 2019, los miembros del equipo deGranger Construction, Integrated Design Solutions (IDS), IBI Group, Motor City Electric y Conti Corporation hicieron historia a medida que su proyecto de centro de datos de diseño y construcción se convirtió en el primero en el estado de Michigan en recibir la Certificación Tier III de Uptime Institute tanto para instalaciones de diseño como para instalaciones construidas.

Este proyecto no solo fue el primero de su tipo completado en el estado, sino que el propietario también encargó al equipo que completara la fase de diseño dentro de un sprint y construcción desafiantes de 12 semanas en poco más de un año. En el siguiente estudio de caso, el equipo del proyecto comparte las mejores prácticas y las lecciones aprendidas de su experiencia.

Un proyecto desafiante

“Al diseñar este proyecto, enfrentamos muchos desafíos más allá de la planificación para la certificación de Tier III”, señaló Joanne Kulbacki, Gerente Sénior de Proyectos de Granger.

Múltiples tomadores de decisiones: Como centro de datos empresarial para un cliente de International Fortune 500, este proyecto incluyó una serie de partes interesadas cuyos intereses necesitábamos coordinar. El Propietario tenía muchas personas involucradas en la aprobación de cada decisión, incluidos líderes de su grupo de TI, diseño de instalaciones, ingeniería, seguridad y divisiones de gestión de riesgos.

Cronograma agresivo: Los objetivos del Propietario para el programa de diseño fueron muy ambiciosos. Su Solicitud de propuesta (RFP) solicitó un enfoque de diseño y construcción basado en criterios limitados, y no incluyó dibujos. El Propietario también propuso un cronograma de diseño de 12 semanas y nos pidió que desarrollemos una estrategia operativa para completar el diseño de acuerdo con los criterios limitados de la RFP.

Nuevos estándares: Por lo general, los proyectos de diseño y construcción se diseñan en función de los requisitos del proyecto descritos en la RFP, con poco aporte adicional del propietario. Sin embargo, este proyecto fue el primer centro de datos del Propietario, y querían asegurarse de que se diseñara y construyera de acuerdo con los últimos estándares de la industria. También querían maximizar la flexibilidad para futuras innovaciones en tecnología de la información, lo que les permitía usar este diseño como plantilla para futuros centros de datos. Para lograr esto, nuestro equipo necesitaba ayudar al propietario a establecer estándares y especificaciones de diseño para una categoría de edificio que no les resultara familiar. Al final, los asesoramos con éxito a través de 39 decisiones de diseño críticas.

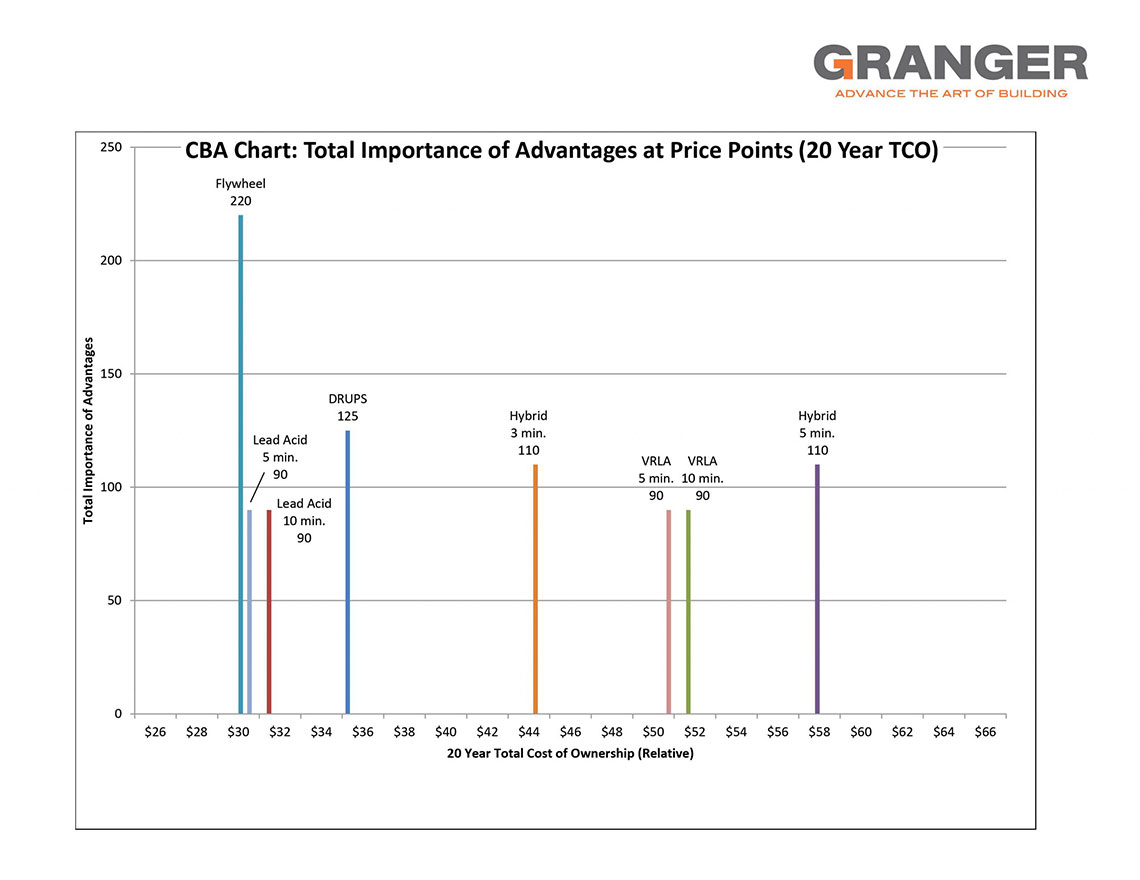

Una de las decisiones de diseño más críticas fue el sistema de suministro de energía ininterrumpida (UPS). No solo influyó en el diseño y el tamaño de las instalaciones, sino que también permitió que el equipo de UPS se comprara durante la fase de diseño, lo que finalmente ayudó a reducir el cronograma de construcción.

La Solución

“Diseñar un centro de datos empresarial en solo 12 semanas es una tarea casi imposible”, continuó Kulbacki. “Pero la mayor razón por la que nuestro equipo tuvo éxito fue nuestra estrategia operativa y agilidad”.

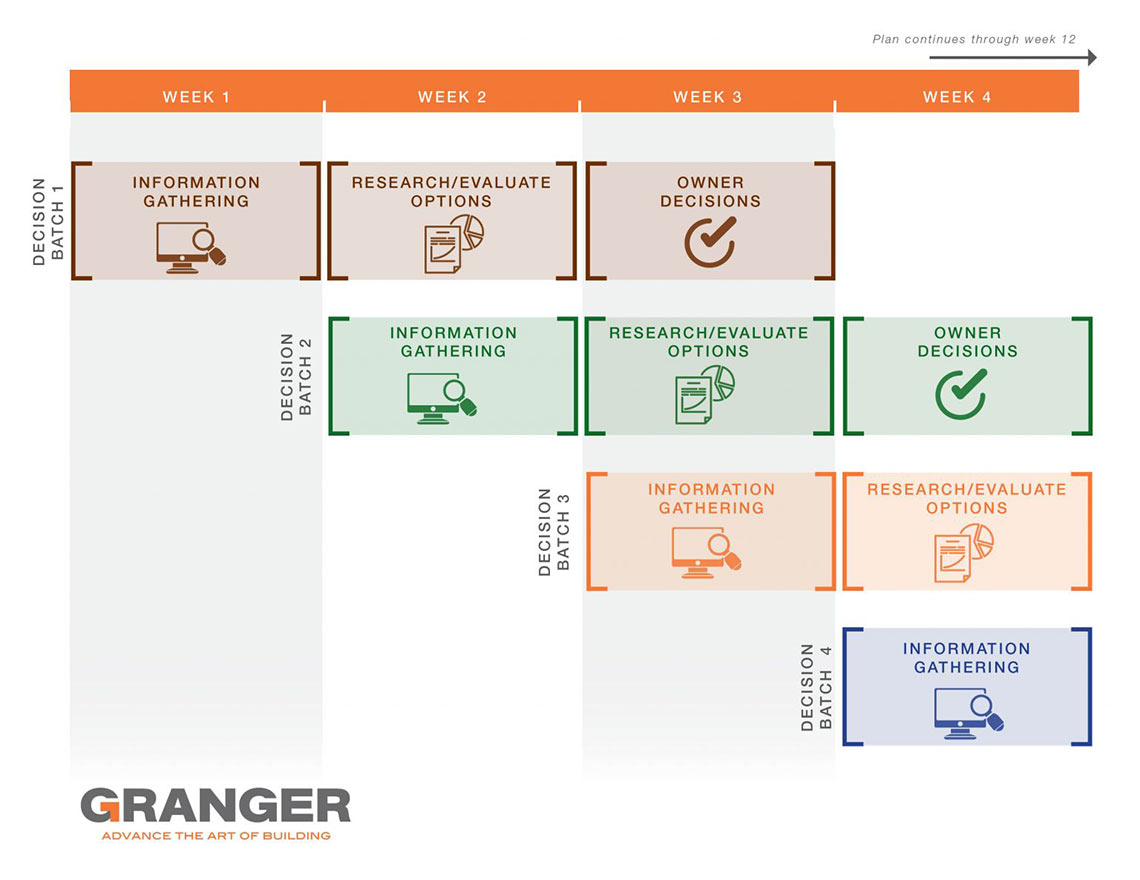

Lotes de tres semanas: Para comenzar, organizamos todas las decisiones de diseño críticas en una serie de lotes de flujo de trabajo que pasaron por un proceso de decisión de tres semanas. En la primera semana, presentamos un nuevo artículo al Propietario que necesitaba una decisión y juntos hicimos una lluvia de ideas sobre múltiples opciones o soluciones que se presentarán en detalle la semana siguiente. En la semana dos, presentamos un análisis detallado de estas opciones, incluido el costo. En la tercera semana, respondimos a cualquiera de las preguntas pendientes del Propietario. Luego, el Propietario decidió una opción o solución. Cada semana, el equipo comenzó un nuevo lote de decisiones a lo largo del ciclo, y para la semana tres de cada ciclo, finalizamos las decisiones de diseño.

“La capacidad de los socios del equipo de diseño para dar un paso atrás con una mente abierta y analizar objetivamente las necesidades del centro de datos del propietario a medida que se evaluaban nuevos conceptos, sopesando la funcionalidad, presupuestando y validando los objetivos a largo plazo, fue fundamental para lograr un diseño exitoso”, agregó Ray Fortier, miembro del equipo de Motor City Electric.

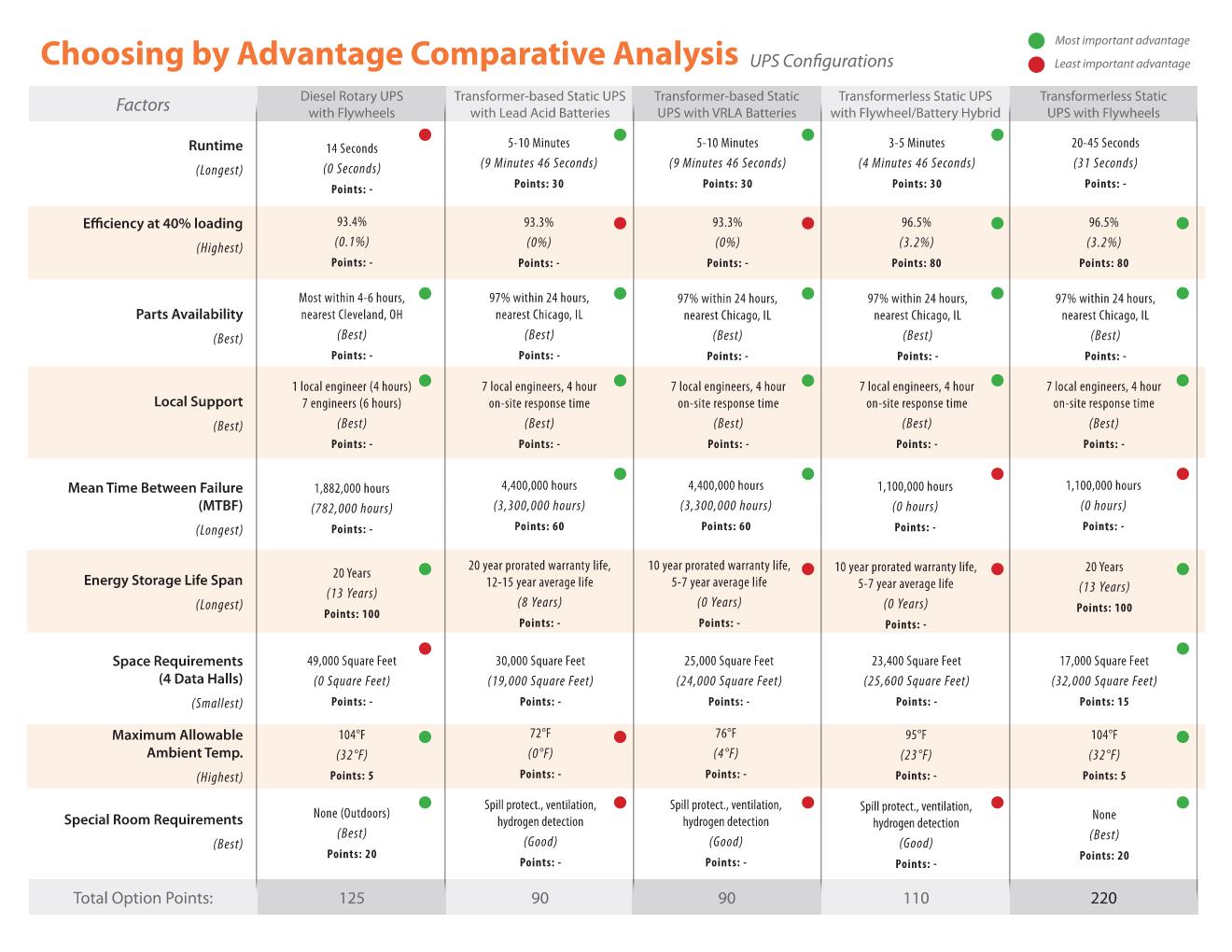

El sistema UPS fue uno de los primeros artículos que presentamos. En la primera semana, trabajamos con el Propietario para establecer varias opciones de UPS, que incluyen UPS estático basado en transformador, UPS estático sin transformador, UPS rotativo y varias opciones de energía almacenada, que incluyen baterías de plomo ácido ventilado (VLA), baterías de plomo ácido reguladas por válvula (VRLA) y volantes. Presentamos nuestro análisis en la semana dos, y el Propietario tomó una decisión en la semana tres. El proceso de lotes de tres semanas permitió al Propietario tomar una decisión informada sobre un tema muy complejo en un período relativamente corto, lo que nos permitió comprar el equipo de UPS al principio de la fase de diseño.

Flujo de reuniones semanales: A lo largo de cada ciclo de tres semanas, también utilizamos un flujo de reuniones semanales efectivo. Todos los martes, nuestro equipo de diseño se reunió con el Propietario para:

- Revisar el presupuesto

- Medir nuestro progreso en el proceso de diseño

- Presentar las opciones de diseño descritas en el plan de lotes de tres semanas

- Tomar las decisiones críticas requeridas esa semana

Realizamos una encuesta plus/delta al final de cada reunión para asegurarnos de agregar valor cada semana. Los miércoles, nuestro equipo de 25 profesionales (socios de ingeniería y comercio) estableció la agenda para la siguiente reunión del martes en función del plan de 12 semanas y los comentarios de los Propietarios. Luego realizamos sesiones de trabajo en grupo específicas de la disciplina según la agenda, donde desarrollamos soluciones/opciones que incluían análisis de costos, cronogramas y costo de propiedad. El resto de la semana (jueves a lunes), utilizamos reuniones breves que duraron de 15 a 60 minutos para terminar de preparar las presentaciones para las reuniones de propietarios del martes.

“Estas reuniones de equipo de diseño multidisciplinario de ciclo rápido eliminaron una mentalidad de “arrojarlo sobre la pared” al final de la fase y permitieron el análisis de la constructibilidad de la mano con las decisiones de diseño”, declaró el gerente de proyectos de IDS, David Giroux, AIA. Este patrón semanal también mantuvo al equipo enfocado y coordinado, mientras sentaba un precedente al principio del proyecto para una toma de decisiones rápida y eficiente.

Participación clave: “Uno de los mayores factores para el éxito con nuestro flujo de trabajo de diseño fue tener a las personas adecuadas en la sala cuando las necesitábamos, así como la coordinación y química sobresalientes entre el propietario, el gerente de construcción, el equipo de diseño y los socios comerciales”, agregó el ingeniero eléctrico de IDS, Justin Kiriazis, PE. Nuestro equipo de diseño contó con expertos en la materia de Motor City Electric, Conti Corporation y otros socios comerciales y proveedores para abordar desafíos específicos en preparación para las reuniones de propietarios del martes. Esto significó que podríamos tener discusiones continuas sobre la constructibilidad durante toda la fase de diseño, junto con el acceso a información de costos continua y precisa basada en las opciones de diseño propuestas.

Por ejemplo, el director mecánico de Conti Corporation, Vic Calleja, y el Sr. El estimador mecánico, Jon Tkac, señaló que fue especialmente eficaz poder trabajar con el equipo temprano para obtener valiosos comentarios sobre los requisitos del sistema mecánico.

“Después de identificar las necesidades mecánicas del Propietario, como la capacidad de megavatios requerida, realizamos una cola de milano de un sistema mecánico para lograr el enfriamiento adecuado requerido, junto con redundancia en caso de cualquier tipo de falla catastrófica, para garantizar que el equipo funcione sin omitir un latido. Trabajando con nuestros socios del equipo, pudimos lograr esta tarea monumental y propusimos nuestro diseño mecánico final que logró los requisitos de certificación Tier III de Uptime Institute”.

Contar con las personas adecuadas en la sala en el momento adecuado contribuyó en gran medida a un análisis eficaz y preciso de las opciones de diseño presentadas, decisiones rápidas por parte del Propietario y cero tiempo de inactividad durante la fase de diseño. La estrecha coordinación entre nuestro equipo de diseño y nuestros socios comerciales y las decisiones rápidas de los Propietarios nos permitieron comprar equipos con anticipación y comenzar los esfuerzos de construcción durante la fase de diseño, lo que nos ayudó a cumplir con el estricto cronograma de construcción. Al establecer una agenda detallada para las reuniones semanales con el Propietario, este tuvo una gran participación de sus expertos en la materia y de los responsables de la toma de decisiones durante todo el proceso; contar con los representantes adecuados del Propietario en la sala, semana tras semana, fue clave para lograr un cambio rápido en las decisiones complejas.

Comunicación visual

“Otra clave para el éxito de nuestro equipo fue la utilización de diversas herramientas de comunicación visual”, afirmó Kulbacki. Con tantos responsables de la toma de decisiones y partes interesadas involucradas, necesitábamos asegurarnos de que hasta los detalles técnicos más especializados se comunicaran de una manera que todos pudieran comprender. Con ese fin, utilizamos diagramas/imágenes simples para cubrir una variedad de temas y garantizar la comprensión equitativa entre todos los participantes del Propietario, independientemente del área de experiencia.

Modelos BIM: “El modelado de información de construcción (Building Information Modeling, BIM) se ha convertido en un estándar para proyectos en todas las industrias, y nuestro equipo encontró esta herramienta de comunicación visual especialmente eficaz para coordinar las vastas complejidades de la infraestructura mecánica y eléctrica dentro de este proyecto de centro de datos de ritmo acelerado”, señaló el ingeniero eléctrico de IDS, Scott Batzold, PE. La documentación de nuestro equipo y la precisión del modelado BIM se convirtieron en factores críticos para permitir el progreso de construcción sin restricciones.

El equipo utilizó BIM para ejecutar detecciones de choques, coordinar diseños comerciales y presentar conceptos de diseño al propietario. BIM también nos permitió comparar opciones y responder preguntas sobre las opciones propuestas. Por ejemplo, utilizamos BIM para explorar el diseño de la sala de datos y determinar la mejor ruta de acceso al piso inferior de la tubería de agua helada y los puntos de acceso para el mantenimiento.

Elegir por ventaja: A medida que avanzamos en el proceso por lotes de tres semanas, nuestro equipo de diseño utilizó Elegir por ventajas (CBA) para ayudar al Propietario a tomar decisiones sobre los temas complejos. Por ejemplo, al elegir el sistema UPS, al Propietario se le presentó una matriz de CBA con cinco opciones y atributos de UPS enumerados para cada opción en función de nueve categorías de atributos. A los atributos se les asignaron puntos ponderados en función de la importancia para el propietario. Un gráfico de los resultados del CBA y el costo total de propiedad permitieron al Propietario ver visualmente que la opción de volantes era la mejor solución. El proceso de CBA hizo que el Propietario se sintiera más seguro en sus decisiones y ayudó a agilizar el proceso de toma de decisiones.

Presentaciones: Creamos presentaciones visualmente ricas para ilustrar contenido de diseño real al Propietario cada semana. Esto ayudó a garantizar la comprensión universal de conceptos de diseño complejos en una audiencia grande y diversa, lo que facilitó decisiones más rápidas.

Paneles: Utilizamos un diseño de tablero para hacer un seguimiento de las métricas principales, la asistencia a reuniones semanales y el progreso hacia los objetivos. En este proyecto, las métricas principales incluyeron los puntos de certificación LEED y los pasos de certificación Tier III de Uptime Institute alcanzados hasta la fecha. Actualizamos este panel antes de cada reunión semanal de Propietarios para reflejar los últimos números.

Metas, funciones y contingencias

“Nuestro equipo está orgulloso de lo que logramos con este desafiante proyecto de diseño y construcción”, señala Kulbacki. “Pero una conclusión importante que aprendimos y enfatizaríamos para los equipos de proyectos futuros es planificar amplias contingencias para cuando las cosas cambien”.

Elimine el concepto erróneo de que no hay espacio para cambiar de opinión o alterar decisiones/diseño con un enfoque de diseño y construcción. Las cosas cambian en cada proyecto, y la mejor práctica es crear un plan de contingencia para absorber estos cambios. Es vital establecer metas claras y responsables clave de la toma de decisiones al comienzo del período de diseño. Sin embargo, debe revisar y recalibrar estas metas y aclaraciones de roles a medida que avanza el diseño y la construcción del centro de datos. Al igual que cualquier cosa en tecnología, ¡lo que es genial hoy podría quedar obsoleto mañana!

Comience en la reunión de inicio del diseño explicando por qué es importante definir claramente las funciones/responsabilidades individuales y designar a los responsables finales de la toma de decisiones.

Es posible que el propietario no sepa exactamente lo que desea al inicio del proyecto, o puede haber brechas de información en la RFP, por lo que debe aclarar estas cosas al inicio del proceso de diseño para que todos estén en la misma página en el futuro.

Esto es especialmente cierto para cualquier persona que se esfuerce por obtener la Certificación Tier de Uptime Institute. Primero debe llegar a un acuerdo con el Propietario y todo el equipo sobre qué elementos de certificación buscar, luego determinar si existe un deseo y disponibilidad presupuestaria para mejorar cualquiera de los sistemas a un Tier nivel superior para mayor confiabilidad.

Certificación y éxito

“Nuestro enfoque de diseño y construcción, flujo de trabajo y sinergia de equipo nos permitió tomar un cronograma de diseño agresivo y lograr no solo la Certificación Tier III para el diseño, sino también para la construcción”, dijo Kulbacki.

“El proceso de Certificación Tier de Tiempo de Actividad fue invaluable para el éxito de nuestro proyecto”, señala Kiriazis. “El consultor sénior Scott Good hizo todo lo posible para ayudar a nuestro equipo de diseño a navegar por los Tier Standards durante el diseño y la construcción de las instalaciones. Su experiencia aseguró que se cumplieran las expectativas del cliente para una instalación de Tier III de alta calidad.

“Fue un honor ser parte de una hazaña tan monumental y única en su tipo”, agregó Calleja y Tkac.

El equipo mantuvo la diversión, la camaradería, el compromiso y la emoción durante todo el proyecto. Esto, además de la actitud de “puede hacer” y el compromiso de todos para asegurar la experiencia y las respuestas, fueron claves para el éxito. También tuvimos un gran proceso de incorporación a medida que el proyecto avanzaba, lo que nos permitió mantener nuestro enfoque de diseño a medida que crecía el tamaño del equipo.

Si bien son agresivos, hay muchos aspectos de este proceso de diseño que alentaríamos a otros equipos de diseño a implementar en su proyecto. Ya los hemos implementado en una instalación hermana para el mismo cliente de Fortune 500.

Nos sentimos honrados de ser el primer equipo en Michigan en usar Design-Build con esta estrategia operativa y lograr ambas certificaciones y unirnos al grupo de más de 60 centros de datos en los EE. UU. que han recibido la Certificación Tier III para Documentos de Diseño (TCDD) de Uptime Institute y la Tier Certification of Constructed Facility (TCCF) para centros de datos completados.